More than 250,000 customers use the vital transport systems of the Storebælt and Øresund fixed links, and soon, the upcoming Fehmarnbelt link. Ensuring that these facilities work around the clock, year-round is crucial. This places high demands on both daily operations and on long-term maintenance. All the structures and facilities must be in top shape at all times. The new technologies make this doable.

From 2D drawings to 3D models

One of the great technological leaps in the digital journey of Sund & Bælt is the transition from manual 2D drawings to digital 3D models. This is the first step towards creating 'digital twins' of the large infrastructure systems.

A digital twin is a living digital model of reality. It digitally mirrors motorways, railways, which together constitute the infrastructure. As an example, a digital twin may simulate the real world, using data from sensors that transmit information directly into the model. It monitors each part of the modelled infrastructure and reports changes throughout its lifetime.

Jens Peter Brorsen, Head of Data and Digitisation, Sund & Bælt, who has worked with the digital twins explains how this tool can be used here and now while also providing data to pinpoint future maintenance:

“We’re working on expanding our 3D models with a variety of data from sensors, images, and other sources, which will continuously provide information about the condition of the infrastructure and indications about when it is time to inspect them. In this way, the digital twin will help us optimise our future operation and maintenance.”

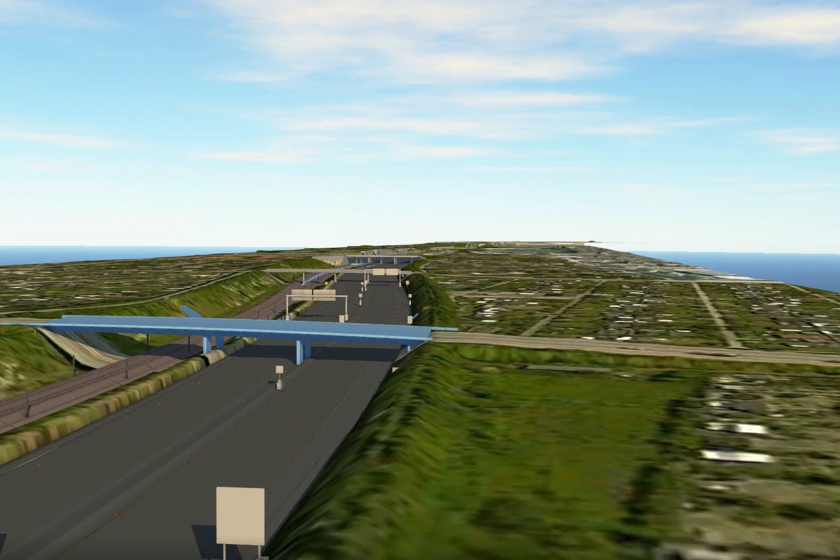

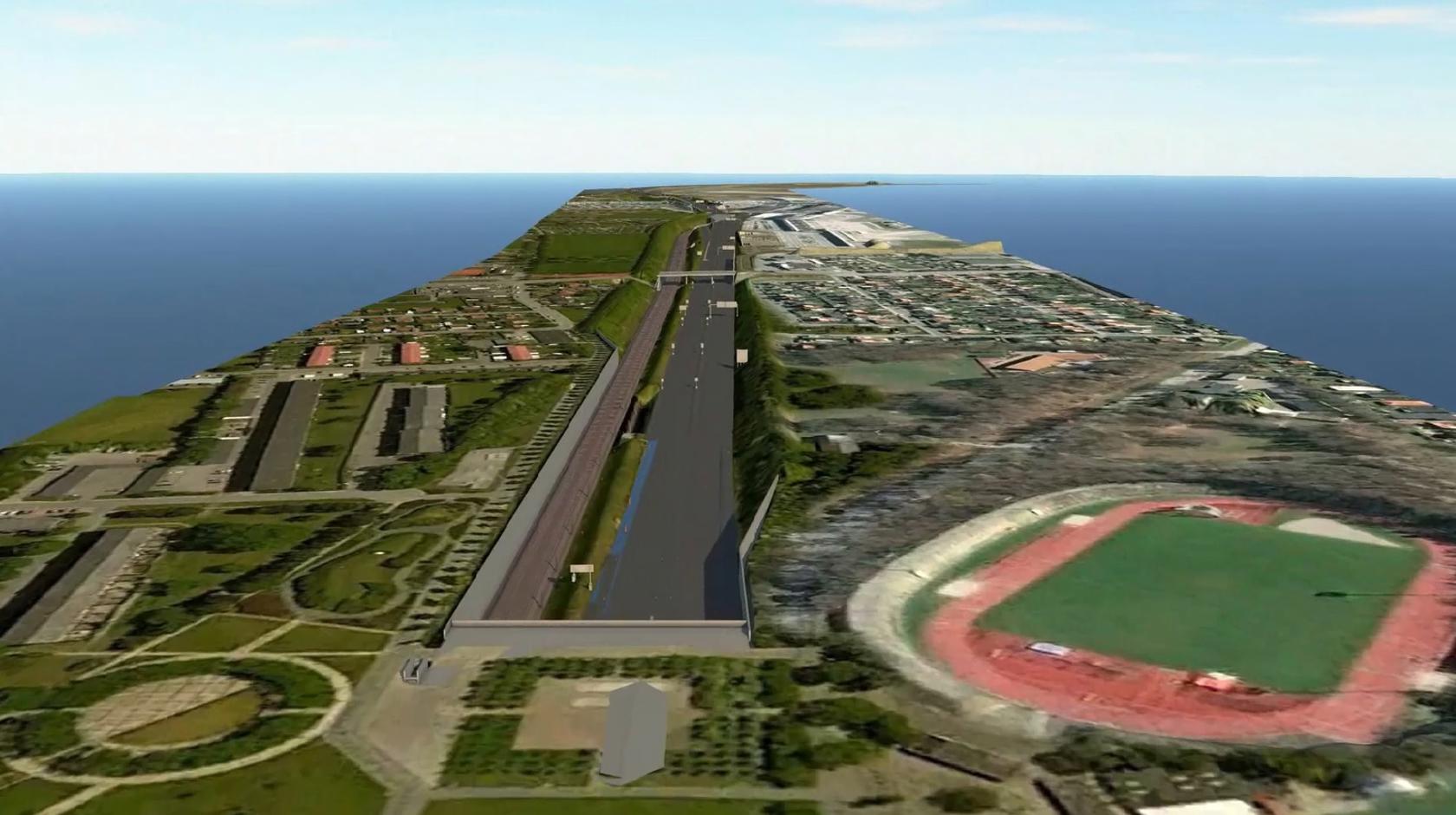

Øresund Landanlæg: first example of a digital twin

The motorway and railway across Amager to Copenhagen Airport and the Øresund Bridge, also known as the Øresund Landanlæg, and owned by Sund & Bælt, constitute one of the most important transport links in Denmark despite its relatively short distance. The large volume of traffic, combined with the complexity of a motorway and railway in a relatively small space, are the reasons why this corridor has been digitally recreated in a 3D model.

“Our job is to incorporate all the components of the infrastructure, e.g. bridges, rails, asphalt and cables, all of which we consider as 'assets', into our 3D model, while also creating a set of digital data for each individual asset. This will make it easier for our employees to plan, measure and get the full picture of the state of the infrastructure right in their office. Our goal is to make it possible to access operating history, work manuals, upcoming maintenance, and specifications directly from the model,” Jens Peter Brorsen explains.

The full digital data set improves monitoring of the infrastructure and planning of maintenance work while reducing errors and time spent on being physically present by Sund & Bælt specialists at the facilities. The objective is to perform continuous maintenance and repairs, with inspections and repairs based on real-time conditions to a greater extent than has so far been the case with inspections performed on a time schedule.

We cannot do it alone

Continuous innovation is crucial for Sund & Bælt to attain the digital twins’ objective. This is why the group is working with partners who are leaders in their fields.

“Working with external knowledge and technology companies, we can develop unique solutions to increase efficiency in our infrastructure. This benefits us as well as our industry in general,” Jens Peter Brorsen concludes.

Sund & Bælt’s subsidiary, Partner A/S, working with in-house experts and external partners, is making sure that knowledge is translated into digital tools and services. The ambition is that solutions to increase efficiency will release funds for new infrastructure and create new growth opportunities for Danish companies that can export the solutions to infrastructure owners and operators in the rest of the world.

- Over the past four years, Sund & Bælt has been working on a digital transformation that will streamline the operation of large infrastructure systems, while extending their service life. This is achieved mainly by implementing digital technology in partnership with external knowledge and technology companies.

- One technological leap is the transition from manual 2D drawings to digital 3D models, or ‘digital twins’. A digital twin is a live, permanent, real-time digital model of the infrastructure, using sensors and other means to input real-time data into the model and providing a current and updated picture of the state of the infrastructure. This allows for easier prevention of damage to concrete, steel and other materials or parts, and in turn strengthens and extends the life of the infrastructure.

- On the Storebælt Bridge, Sund & Bælt has succeeded in developing and implementing new methods for analysing concrete and steel structures, making maintenance work on the bridge far more timely, precise and efficient. Early results indicate a two per cent reduction in annual operating costs until 2023 instead of previously projected increases.

- In addition to cost savings, a climate benefit will be realised, as digital maintenance can extend the service life of the individual pieces of infrastructure. A service life extension by 100 years of the concrete and steel superstructure of the Storebælt link alone has been calculated to save 750,000 tonnes of CO2.